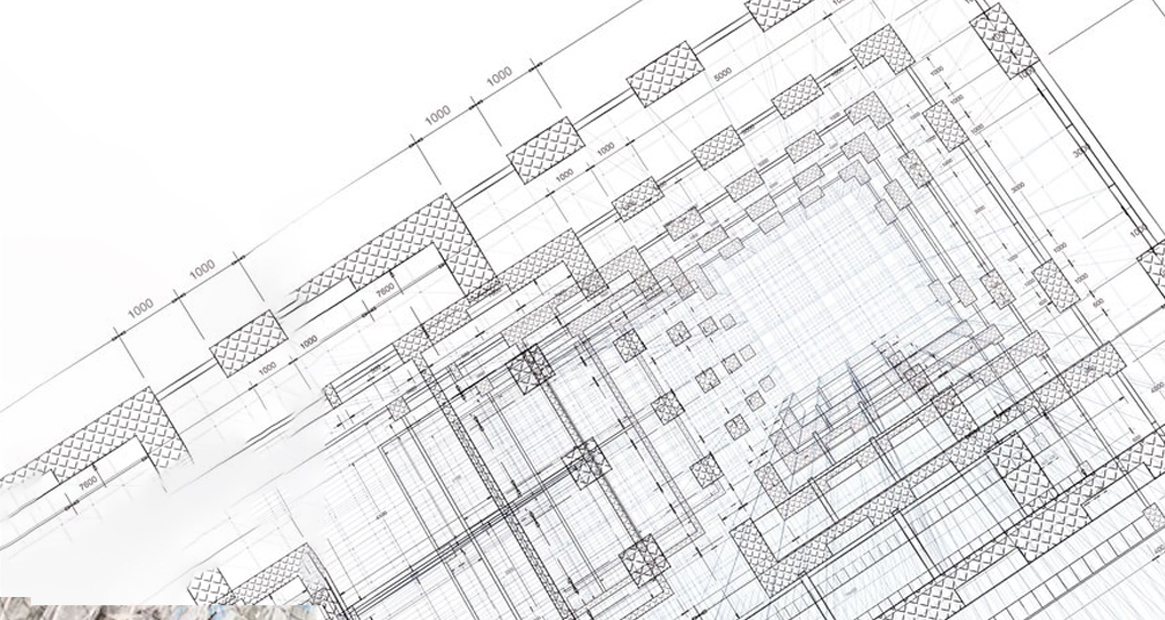

Rebar Detailing

Accurate. Efficient. Reliable – Rebar Detailing That Builds Confidence

At Kryptos Rebar, we specialize in rebar detailing services that ensure strength, accuracy, and constructability in every structure. Our expert detailers use advanced tools and global standards (ACI, BS, IS codes) to produce error-free, clash-free, and fabrication-ready rebar drawings.

Whether it’s a high-rise, bridge, or industrial plant, we deliver precise reinforcement detailing that saves time, minimizes wastage, and boosts project efficiency.

Why Choose Kryptos for Rebar Detailing?

Our process-driven approach and technical expertise make us the preferred choice for builders, contractors, and structural consultants worldwide.

100% compliance with design and code standards.

Reduce steel wastage with precise bar schedules.

Automated clash detection and multi-level quality checks.

ACI, BS, IS, AS/NZS, and Euro standards.

Timely delivery without compromising quality.

Our Rebar Detailing Capabilities

From concept to construction, Kryptos covers all aspects of reinforcement detailing.

- Foundation, slab, beam, column, and wall detailing

- BBS (Bar Bending Schedule) preparation

- Precast and post-tensioned structure detailing

- Rebar shop and fabrication drawings

Why Accurate

Rebar Detailing Matters

Every millimeter matters in rebar. Inaccurate detailing can lead to site delays, cost overruns, and structural inefficiencies. Kryptos ensures dimensional accuracy, coordination, and constructability to make your construction faster, stronger, and smarter.

Our Rebar Detailing Capabilities

From concept to construction, Kryptos covers all aspects of reinforcement detailing.

Let’s start your

Next project with Kryptos

Rebar Detailing

Services by Kryptos Rebar

Rebar detailing is the process of preparing detailed drawings for reinforcement placement. It ensures accuracy in bar lengths, bends, and quantities—critical for structural integrity and cost control.

We use Rebar CAD, Auto CAD, Bluebeam and ASA for precision detailing and Estimation.

Yes, Kryptos Rebar follows ACI, BS, IS, AS/NZS, and Euro Code standards for global project compatibility.

We work with residential, commercial, bridge, and industrial projects globally.

Every drawing undergoes a two-level quality check, ensuring dimensional, code, and constructability accuracy.

Let’s start your

Next project with Kryptos